Time:2025-07-25

Sapphire material relies onSuper hardness(second only to diamonds, with a Mohs hardness of 9)Good thermal conductivity(40 times that of stainless steel)Good chemical inertness(Can resist strong acids and bases)Good light transmission range(covering ultraviolet to infrared) has become the preferred material for many product components. Next, let's take a look at the common sapphire components of Xinyuan Optics.

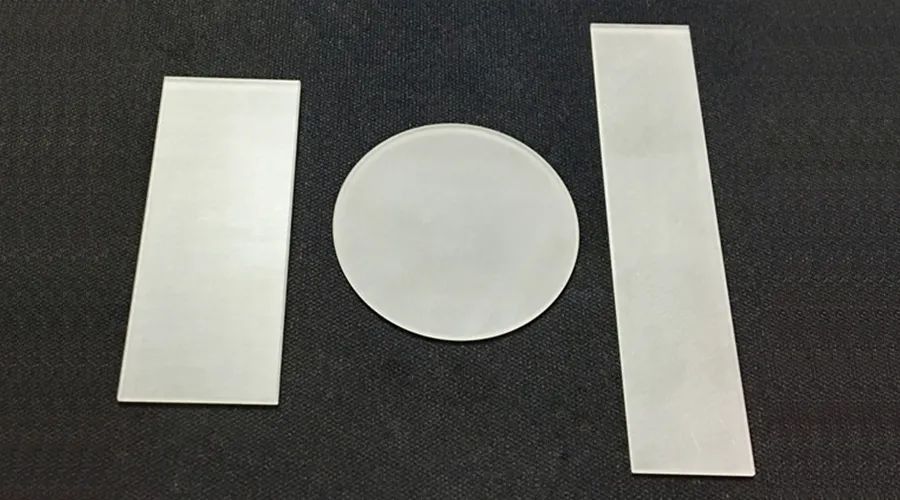

*The picture shows a successful case of customized sapphire components for Xinyuan Optics

Rotors and stators are components in the field of industrial machinery,To prevent the stator and rotor fromdamageandStrong frictionThe raw materials need to have high-strength characteristics.Sapphire material has excellent wear and scratch resistance, and is widely used in the production of rotor and stator components. Many rotors and stators are made ofSapphire materialmake.

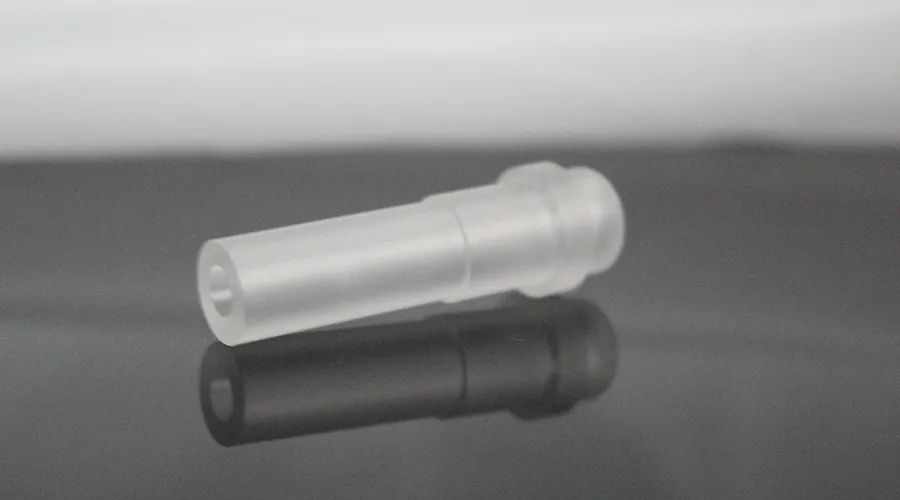

The plunger rod is mainly used for high-performance applicationsLiquid chromatography pump、Medical analysis pump、oil pumpAnd variousHigh and low pressure pump.The sapphire plunger rod is made of artificial corundum single crystal, which has the advantages of wear resistance, corrosion resistance, thermal stability, and chemical stability.

The application of circular sapphire tube electronic components is becoming increasingly widespread in today's society, and many people have a clear understanding of the use of sapphire and use it as a component in their own industry. One important advantage of sapphire is that it is sufficienthardTherefore, it can be used as a component to support the core of the machine. Although sapphire has some special properties, it is difficult to process and manufacture parts. It is necessary to control the surface quality well to avoid occurrence during the processingpit、traceEspecially the polishing process, it directly affects the surface quality of the components. Therefore, it is necessary to use high-speed precision grinding combined with precision grinding and rough grinding to improve the surface roughness of the processed parts, so that the quality and accuracy of the processed parts can meet the standards.

The current mainstream materials for electronic cigarettes are still mainly chemical resistant plastics and ceramics. Sapphire is often used for key protective or sensing components due to cost factors, and its large-scale application depends on process optimization and market demand. howeverSapphire, with its excellentchemical stability、high temperature resistanceWith a melting point of over 2000 ℃ and high hardness, it can be used as a supporting substrate or protective layer for atomization cores. Its inert nature can prevent catalytic reactions of e-liquid components, ensuring the safety and taste purity of the atomization process, while extending the life of key components.

*The picture shows a successful case of customized sapphire glass mirror by Xinyuan Optics

In addition to the common sapphire components mentioned above, Xinyuan Optical's sapphire component products are also widely used inFire protection equipment detection window (such as flame detector window panel),Sapphire Home Appliance Operation Display Light,Diving camera sapphire protective lens,Experimental observation of sapphire window plateWait.Welcome friends with relevant needs to come for consultation, sample viewing, and inspection~

*The picture shows other sapphire and sapphire components of Xinyuan Optics

Tel

Mobile phone

Customer service

TOP