Time:2025-04-11

Sapphire high-strength glass, as a material with unique physical and chemical properties, has demonstrated advantages in multiple high-tech and precision manufacturing fields. However, it is precisely the extraordinary properties of this material that make it a major challenge in the processing industry. This article will explore the processing difficulties of sapphire high-strength glass, as well as the special techniques and methods adopted to overcome these difficulties.

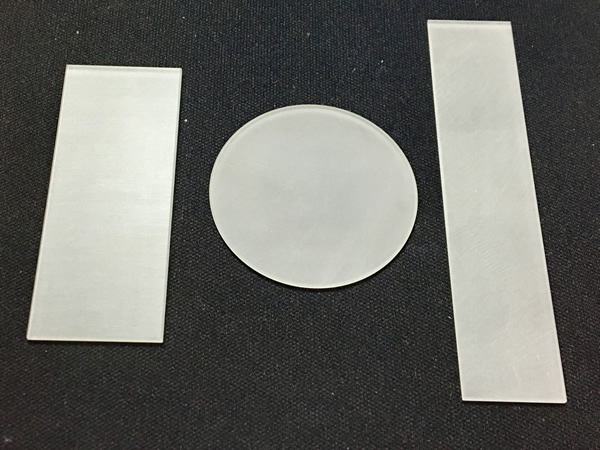

Sapphire high-strength glass is essentially a transparent material crystallized from pure alumina at high temperatures. It is not glass in the traditional sense, but a hard crystal with a hardness of up to 9 on the Mohs scale. This hardness endows it with high wear resistance and scratch resistance, making it an ideal material for watch mirrors, smartphone screen protectors, and precision optical instrument lenses. However, it is precisely its high hardness and brittleness that make machining exceptionally difficult.

During the processing, high hardness and brittleness are challenging factors. Traditional mechanical processing methods, such as cutting, grinding, etc., are prone to material fracture or damage when processing this material. Therefore, special processing techniques and equipment are needed to reduce stress and damage during the processing. These special technologies include precision grinding, polishing, laser processing, electrochemical processing, and ultrasonic processing. These technologies not only require a high level of professional knowledge and experience, but also require a deep understanding of the characteristics of sapphire high-strength glass.

In addition, the wear and tear of processing tools is also a serious problem faced when processing high-strength sapphire glass. Due to the high hardness and wear resistance of the material, the tool will suffer severe wear during the processing, which not only increases the processing cost but also shortens the tool's lifespan. To solve this problem, special tools and abrasives such as diamond tools and abrasives, as well as special coating techniques, are usually required to improve the durability and efficiency of the tools.

In the fields of electronics and optoelectronics, the application of sapphire high-strength glass typically requires high-precision shape and size control. This further increases the difficulty of processing, as traditional processing methods are unable to meet these high-precision requirements. Therefore, more precise machining techniques and equipment are needed to ensure the quality and performance of the product.

In addition to high hardness and brittleness, processing cost is also a challenge that needs to be overcome. Due to the difficulty of processing, special processing methods and equipment are required, resulting in relatively high processing costs. This limits the use of sapphire high-strength glass in certain application areas, especially in cost sensitive markets.

Precision grinding and polishing are important steps in the processing of sapphire high-strength glass. This step not only requires high precision and surface quality, but also precise control of various parameters during the machining process. For example, the type, concentration, pH value, grinding time, and pressure of the grinding fluid can all affect the quality and performance of the product. Therefore, advanced equipment and processes are needed to ensure the stability and controllability of the grinding and polishing process.

Laser processing technology is also an effective method for processing sapphire high-strength glass. The laser beam can accurately act on the surface of the material, achieving high-precision cutting and drilling operations. Meanwhile, laser processing also has the advantages of fast processing speed and small heat affected zone, making it suitable for occasions with high requirements for processing accuracy and surface quality. However, precise control of parameters such as laser power, spot size, and processing speed is also necessary during laser processing to avoid the occurrence of cracks and defects.

Electrochemical machining and ultrasonic machining are also optional methods for processing sapphire high-strength glass. Electrochemical machining utilizes the principle of electrochemistry to remove a layer of material surface through chemical reactions in the electrolyte. This method is suitable for processing complex shapes and small-sized parts. Ultrasonic processing utilizes the mechanical energy generated by ultrasonic vibration to remove a layer of material surface. This method has the advantages of high processing efficiency and wide applicability, but it also requires precise control of processing parameters to ensure processing quality.

Sapphire high-strength glass, as a high-performance material, has demonstrated its enormous potential and value in multiple high-tech and precision manufacturing fields. Although there are many difficulties and challenges in its processing, with the continuous progress and innovation of technology, we believe that these difficulties will eventually be overcome.

Tel

Mobile phone

Customer service

TOP